Payment methods accepted

Punch Down, Feed-Through, and Toolless Keystone Ethernet Patch Panels Explained

Written by Dave Harris, trueCABLE Technical Specialist, BICSI INST1 Certified

Chances are, if an Ethernet installation involves more than one or two cable drops, it’s also going to involve the use of a patch panel. A patch panel provides a common termination point for all of the cables that will eventually connect to a common distribution device, such as a switch or router. An Ethernet patch panel consists of a method to permanently attach the solid copper cables that are part of the permanent infrastructure (horizontal cables) to outlet ports where flexible patch cords can be connected between the patch panel and a switch.

Figure 1. Patch panels at work. The yellow cables are called “patch cables” or “patch cords” and they connect from the output ports on the front of the patch panels (the black components) to the switch (the silver component at the bottom). The blue cables in back connect the rear (input) of the patch panel to individual user stations or devices. The blue cables are also called “horizontal” cables.

A patch panel is also a necessary component to an installation involving shielded Ethernet cables. The shield and drain wire contained in the cable must have a path to the building ground system, and use of a shielded patch panel is the best and sometimes only way to bond shielded cable to ground.

There are different types of patch panels. It’s tempting to say that they come in all shapes and sizes, but they really don’t. Most patch panels are designed to fit a standard 19-inch or 23-inch equipment rack, and some are configured to mount on a wall or in an enclosure. The rack-mounted panels usually provide either 24 or 48 individual ports, and are sized to fill either one or two rack units when installed.

The differences that we are concerned with in this article are the differences in how the patch panels are connected to the horizontal network infrastructure cables. And for that there are basically three different types: Feed-Through, Monolithic, and Toolless.

Feed-Through Patch Panels

We include feed-through patch panels here because they can be the simplest to install. Some people refer to “feed-through” patch panels as “pass-through” patch panels. We prefer to avoid confusion with our pass-through 8P8C connectors, so we are on the “feed-through” team. Each RJ45 output port on the front of a feed-through patch panel is connected to an RJ45 input jack on the rear of the panel. On this type of patch panel, patch cords are used for the connection from the patch panel to the switch, and also for the connection of the patch panel to the user device, often located in another area of the building. Feed-through panels are useful in cases where the installation is temporary, confined to small spaces, or in cases where the installer is not prepared to terminate solid copper cable.

Feed-through patch panels are Category rated. This means that the panel is designed to handle certain Ethernet cable speed ratings. The Category rating is backward compatible with previous Categories, but not forwards compatible. For example, a Cat6A patch panel can handle Cat5e through Cat6A. A Cat5e patch panel will only ever be able to handle Cat5e and cannot be used for higher speed needs. A replacement patch panel will be required. The wisest choice, if purchasing this type of patch panel, is to pick Cat6A even though you may not be using Cat6A Ethernet cable yet.

Figure 2. Feed-through patch panel. There are RJ45 ports on both the front and rear of the device.

Monolithic Patch Panels

Like a feed-through patch panel, a monolithic patch panel has permanently-installed RJ45 output ports. These ports are connected to the solid copper infrastructure cable using punch-down 110 IDC terminals. In a monolithic patch panel, these IDC terminals are also permanently-installed components of the patch panel. To install the panel to the permanent cables, each conductor of every Ethernet cable must be individually secured using a 110 punch down tool.

Like feed-through patch panels, monolithic patch panels are also Category rated. Again, the wisest choice, if purchasing this type of patch panel, is to pick Cat6A even though you may not be using Cat6A Ethernet cable yet.

Figure 3. Monolithic patch panel. There are RJ45 ports on the front of the device.

Figure 3. Monolithic patch panel. There are RJ45 ports on the front of the device.

Figure 4. Monolithic patch panel. There are punch-down 110 IDC terminals on the rear of the device.

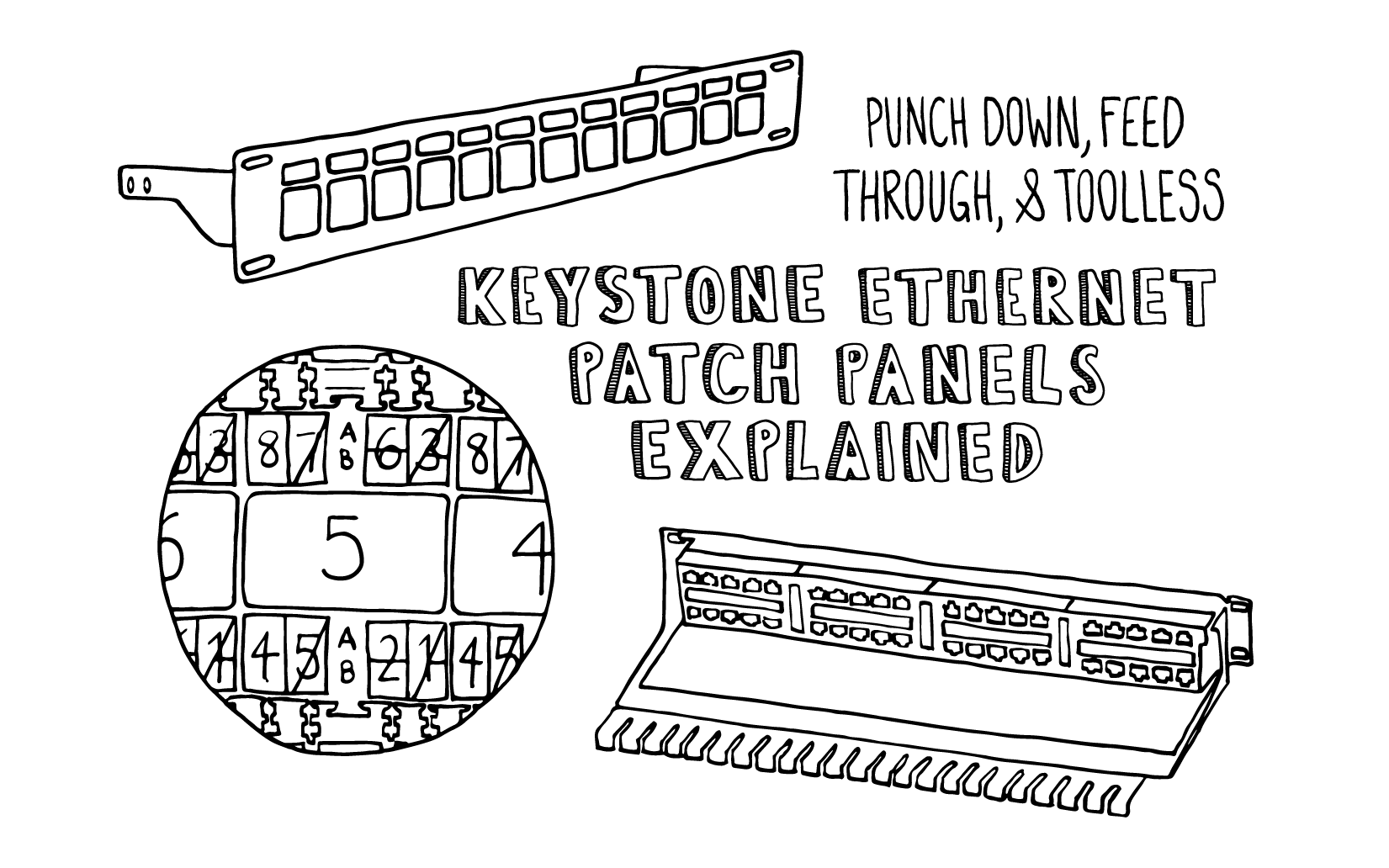

Toolless (Keystone) Patch Panels

A “Toolless” patch panel does not have the 110 punch down connections on the back. It also doesn’t come with RJ45 ports installed in the front. In fact, a toolless patch panel only consists of a metal frame with standard sized openings for mounting of keystone jacks. Because a toolless patch panel doesn’t come with any of the electrical connectivity required for the panel to function, it is often called a “blank” or “unloaded” patch panel.

Toolless keystone patch panels are Category agnostic for the most part, although there are some “gotchas” involved. Shielded toolless patch panels are required for shielded Ethernet keystones and cable and may accept ANY Category rating. The shielding prevents alien crosstalk issues with Cat6A. Shielded toolless patch panels are also very versatile in that they will also accept unshielded keystone jacks and unshielded cable providing maximum flexibility, with the caveat that you may not use Cat6A operating at 10G. Your maximum speed on unshielded runs is Cat6. Your shielded keystones and Ethernet may be Cat6A operating at 10G, however.

Figure 5. Front of toolless patch panel.

Figure 6. Rear of toolless patch panel, shielded.

If you wish to use unshielded Cat6A cable and unshielded Cat6A keystones and operate them at 10G, this will require a “3D stagger” toolless patch panel to avoid ANEXT or alien crosstalk. The ports are offset in multiple dimensions to avoid EMI (electromagnetic interference) at the keystone jack. This phenomenon is only associated with operating your cable and keystones at frequencies exceeding 350 MHz, which means Cat6A which operates at 500 MHz. Cat6 operates at 250 MHz and Cat5e operates at 100 MHz, so those Categories are not susceptible to this issue.

Each keystone jack contains both the RJ45 port for the front of the rack and the 110 punch down IDC connectors for attachment to horizontal cables. Each keystone jack conforms to a physical size standard so they will snap into patch panels and wall faceplates that are built to the “keystone” standard. The keystone standard is adhered to by any component that uses the term “keystone” in its description, regardless of manufacturer.

Figure 7. Keystone jack, terminated to blue horizontal cable and connected to gray patch cord.

A 24-port toolless keystone patch panel can accommodate twenty-four keystone jacks. But if you need fewer than twenty-four, you can purchase and install only the number that is needed and save money on unused ports. There are inexpensive blank inserts that meet the keystone standard, if needed to cover unused keystone openings. Also, if a port ever wears out or is damaged, only the affected keystone jack needs to be replaced, and not the entire patch panel.

A toolless keystone patch panel can also be used to mount keystone couplers. Couplers have RJ45 ports at both ends. When a patch panel is fitted with couplers instead of jacks, the result is the functional equivalent of a feed-through patch panel.

Figure 8. Shielded keystone coupler connected to two shielded patch cords.

So you can use your toolless keystone patch panel to build the equivalent of either a monolithic patch panel or a feed-through patch panel. You can even use it for keystone jacks and keystone couplers at the same time. But, that’s not all. There are keystone fittings for coaxial cables, HDMI cables, audio connections, and even fiber optics.

There are still applications where monolithic patch panels are useful, but these are usually situations that require large numbers of cables such as data centers and large campuses. For most other installations, especially those that deploy multiple types of media, a toolless keystone patch panel is the most economical and versatile choice.

Happy Networking!!

trueCABLE presents the information on our website, including the “Cable Academy” blog and live chat support, as a service to our customers and other visitors to our website subject to our website terms and conditions. While the information on this website is about data networking and electrical issues, it is not professional advice and any reliance on such material is at your own risk.